The low frequency of the balance wheel made it impossible to improve the accuracy of the present mechanical watches. Therefore the Bulova Watch Company Switzerland, knowing that the American army was in need of a better time base for their instruments, asked the Swiss engineer Max Hetzel in 1952 to look into the possibility of the application of a higher frequency in a watch.

Max Hetzel was born in Basel in 1921, graduated in 1946 at the Zurich Federal Polytechnic School as an electronic engineer, worked on TV and Communications and joined the Bulova Watch Company of Bienne, Switzerland, in 1948. This outstanding engineer was the first one to use an electronic device, a transistor in a wrist watch. Thus, Max Hetzel developed the first watch in the world that truly deserved the qualification “electronic”: the world-famous “Bulova Accutron”.

- 1953 Max Hetzel receives the first useful transistors, the “CK 722”, from Raython USA and produces his first working model by hand. The length of the tuning fork was five centimeters. The patent application is filed in Switzerland on June 19th 1953 under no. 312290.

- 1954 The ATO electronic pendulum clock is shown at the CIC in Paris, the first clock in the world with a transistor and without electrical contacts. In June, the first useful batteries suitable for watches, invented by Mallory, become available. In November, the first prototype wristwatch is made to function.

- 1955 Eight watch-sized models are produced in Bienne. In Switzerland many doubted whether “The Accutron” would become successful.

- 1956 The president of the Bulova Watch Co. in New York, Arde Bulova, and his engineers become enthusiastic about the tuning fork system.

- 1959 Max Hetzel goes to New York with his family and becomes Chief Physicistat the headquarters in Jackson Heigts, New York. The Bulova Accutron is developed by team work of two scientists: Max Hetzel and William O. Bennett. The start of the production-engineering phase takes off.

- 1960 On October 10th, the new president of the Bulova Watch Co., Omar N. Bradley, ex-chief of staff of General D. Eisenhower and known for his participation in the Normandy Offensive, announces the Bulova Accutron caliber 214, the first electronic watch in the world. Cased in steel, gold or platinum, the number of parts had been dramatically reduced to a mere 27 of which only 12 were moving parts. By comparison, a self winding watch at that time contained about 136 parts, 26 of them moving. The sale of the Accutron starts on October 25th.

- 1964 The “Bulova Accutron” is chosen to be buried for a time period of 5000 years on the grounds of the New York World Fair in order to save it for future generations as an example of one of the 44 most innovative objects to be invented during the last two and a half decades.

- 1964-1970 In different trips into space with the “Explorer” and the “Apollo”, the “Bulova Accutron” is used by astronauts with full satisfaction.

- 1966 The first tuning fork wrist watches are registered at the Observatory of Neuchatel by Ebauches S.A. and by C.E.H. of Neuchatel.

- 1973 At this time four million “Bulova Accutrons” have been sold since production started.

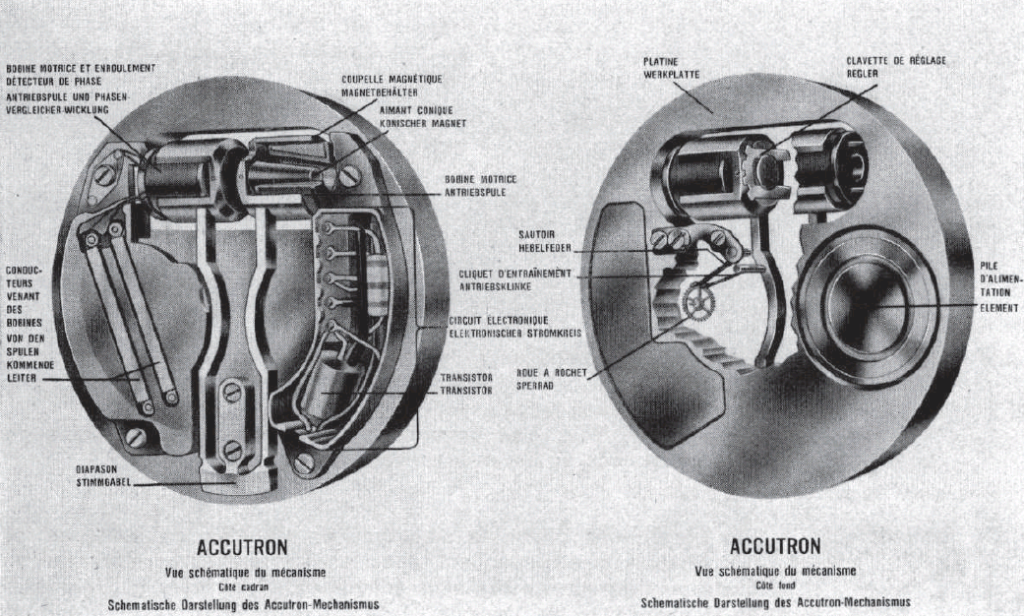

Description of the Accutron

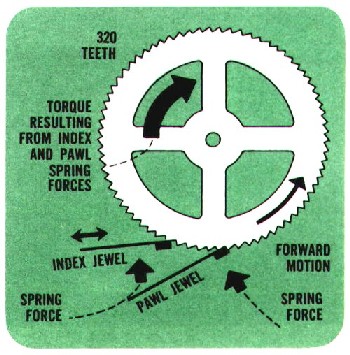

The “Bulova Accutron” has a frequency of 360 oscillations per second (360 Hz). The vibration of the tuning fork is controlled by a transistorised circuit in the following way: When the left magnet on the tuning fork moves to the right, the phase-sensing coil generates an induction voltage on the base of the transistor. The transistor “switches on”, becomes a conductor instead of a resistor and the electrical current is able to start flowing through the right circuit. The drive-coil becomes a magnet and gives an impulse to the permanent magnet. The movement of the permanent magnet in the driving-coil also causes an induction voltage opposing the power cell voltage. The result is a very small electric current and a prolonged battery life. The problem of turning the linear motion of the fork into a circular motion of the hands is solved in the following way: the index jewel is connected to the fork and pushes the ratchet wheel one tooth forward, the pawl jewel is fixed to the watch frame and prevents the ratchet wheel from revolving backwards. The ratchet wheel was an outstanding technical achievement: 2.4 mm in diameter, 0.04 mm thick and 300 teeth, each 1/100 mm high. In one year it revolves 38 million times. To protect the ratchet system, the Accutron may be set only by turning the hands in a forward direction.

Like conventional watches, Bulova Accutrons have a train of gear wheels to drive the hands. And that is basically where the similarity ends. In an Accutron, there are two areas of special interest to us. One is the Electronic Circuitry and the other is the Index Mechanism.

The Electronics

While it is relatively simple, it is nevertheless interesting how the electronics driving the Accutron works. The electronic circuit combined with the tuning fork forms a simple oscillator. Each of the ends of the tuning fork has a little magnet on it. The fork provides the resonant or tuned part of the circuit. Both of these magnets are surrounded by a coil of very fine wire attached to the body of the watch. Power from the battery flows through the transistor, and then through both of the driving coils. One of the coils (the one which is attached to the plate holding the transistor and its components) also has a secondary coil built into it. When the fork springs one way, this secondary coil provides a feedback voltage which cause the transistor to almost stop the flow of current in the driving coils, and stop driving the fork. When the fork springs back the other way, this feedback coil generates a “reverse” voltage, which causes the transistor to allow current to flow in the driving coils again. The fluctuating current in the driving coils produces a varying magnetic field, which alternately attracts and repels the tuning fork magnets. Thus it keeps on vibrating. The system is self-regulating. If the watch receives a jolt which adds to the fork vibration, the circuit automatically reduces power to the fork until it reaches the normal amplitude of vibration. The reverse is also true. One of the more interesting features of the electronics are the coils themselves. Each Accutron coil has 8,100 turns of insulated copper wire of 0.015mm diameter (or about 1/2000th of an inch). That equates to about 80 meters (or nearly 90 yards) per coil. The wire is about one-third the thickness of a human hair. Truly Amazing!

The Index Mechanism

This mechanism provides the means for converting the vibrations of the tuning fork into rotary motion. Even today, it is considered a truly remarkable engineering accomplishment. Though the dimensions of the working parts are incredibly small, the operation of the index mechanism is elegantly simple, and its robustness and reliability legendary. Nevertheless, it is very delicate and requires special handling techniques during servicing and adjustment. The index wheel can be destroyed by simply touching it on its rim. It must be handled by its pinion only. It consist of two very fine flat springs (or “fingers”), each with a small ruby jewel cemented with epoxy onto one end. One of the springs (the pawl finger) is attached to the body of the watch by a small movable carrier and post. The other (the index finger) is attached to a post mounted on one arm of the tuning fork. The jewels of each finger rest on a special ratchet wheel (the index wheel) which has very small triangular shaped teeth. These teeth are so small, they cannot be seen without the aid of a microscope. The positions of the index and pawl jewels relative to each other is adjusted by moving the pawl jewel carrier. Correct adjustment is necessary to allow for variations in fork amplitude during the life of the battery. This is known as “phasing” the index mechanism, and requires good watchmaking skills, experience on Accutrons, and a good understanding of the operation of the index mechanism to be carried out correctly. In operation, when the fork moves towards the index wheel, the index jewel pushes the wheel around slightly more than one tooth. The wheel is then locked in place by the pawl jewel, so when the fork and index jewel moves back away, the index wheel stays stationary. This occurs once for every vibration of the fork, or 360 times a second for a 214 or 218 Accutron movement. The index wheel of a 218 movement is 2.40mm (0.095″) in diameter and has 320 teeth, each of which is about 0.01mm high (0.0004″) and 0.02mm (0.0008″) wide. The index and pawl jewels are perfect little square blocks of synthetic ruby, 0.18mm (0.007″) square and 0.06mm (0.002) thick. How these parts were manufactured has remained a closely-guarded secret.

Accutron watches are unique in that they were the first electronic watches to dispense with the traditional “balance wheel and hairspring” as used in mechanical watches and other early battery powered watches. Hence they are of great historical interest, as well as still being a very practical and accurate means of timekeeping. Departing from tradition, they use a tuning fork, not unlike those used by musicians for tuning an instrument. They are inherently more accurate than balance wheel watches for a number of reasons. The accuracy of a traditional balance wheel watch is dependant on many factors. Friction in the pivots (bearings) due to changes in the quality of the lubricating oil play a significant part in the ability of a mechanical watch to maintain accuracy and consistency of rate. Also, the condition of the mainspring and gear train driving it is very important. The rate of Tuning Fork watches is affected much less by lubrication, though it is still necesary for the correct functioning of the watch. The other major factors affecting accuracy of any mechanical watch are temperature changes and errors due to position (ie. how gravity effects it’s operation in different orientations). Tuning fork watches are inherently far less affected by these problems. The fork has no bearings. It is far easier to “build in” temperature compensation into a Tuning Fork than into a circular balance wheel and it’s hairspring. Gravity affects Bulova tuning forks in only 2 orientations (tines up and tines down) compared with the usual 5 positions of good quality balance wheel watches. (dial up, dial down, winder up, winder right, winder left). The tuning forks of the ESA movements have virtually zero positional error. A balance wheel vibrates at usually 2 1/2 times a second, whereas the tuning fork hums at 300-720 times a second, depending on the model. Modern mechanical watches vibrate as fast as 5 times a second, in an attempt to improve their accuracy by making the balance wheel lower in mass and size, thus reducing their susceptibility to external influences.

Only Watchmakers of the highest skill can adjust a balance wheel watch for its best possible performance under all conditions. Repairing and adjusting tuning fork watches is considerably easier, as there are no adjustments apart from the index mechanism, which converts the vibrations of the tuning fork into rotary motion. Of course, skill and experience is still needed to adjust the index mechanism correctly.

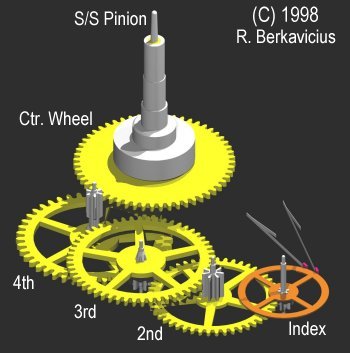

The Gear Train

Another interesting difference between Tuning Fork watches and Balance Wheel watches is the flow of mechanical power in the mechanism. A traditional watch has a mainspring which stores the energy to drive the gears. This energy starts off strong at the mainspring and is slowly diminished in torque through the train of gears until it is suitable for use by the balance wheel. How much loss of energy occurs in this process is again a function of the quality of the bearings and the state of lubrication. The accuracy of the conventional watch is strongly dependant on the constancy of the power which finally arrives at the balance wheel.

In a Tuning Fork watch the power flow is the other way around. The fork drives the gear train, as opposed to a balance which is driven by the gear train. The forces on the gear train of the tuning fork watch are far less, and the quality of the bearings and lubrication are of much less consequence to its accuracy than is typical for a balance-wheel watch. Nevertheless, they are still susceptible to problems due to dirt and poor lubrication as any precision mechanical item is, and maintenance of an Accutron is often overlooked because of their inherent accuracy and reliability. If maintained correctly, they could be expected to last a long time, as the forces on the bearings are so small. In summary, we can see that the gear train of a conventional watch performs two functions: it drives the hands and transmits power to the balance wheel. In a tuning fork watch, it only drives the hands.

All above from Mark Sirianni Watch Repair